How AI Helps Reduce Fabric Wastage: Smarter Cutting, Better Designs, Lower Costs

Introduction

Fabric is the heart of the textile industry. Every meter has value. Every centimeter wasted is money lost. For decades, fabric wastage has been a silent problem affecting small tailoring units, boutique designers, large garment factories, exporters, and even global fashion brands.

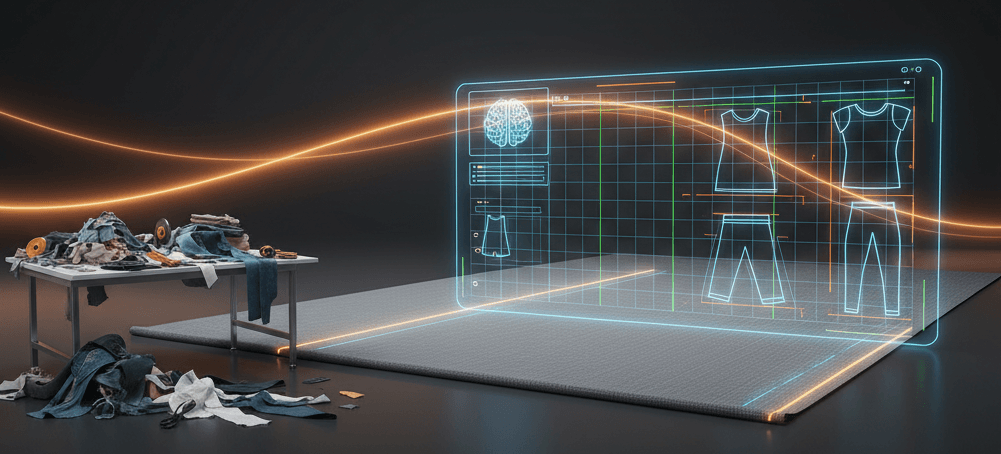

But today, something powerful is changing this old system. Artificial Intelligence (AI) is entering cutting rooms, sampling departments, design studios, and production floors, offering solutions that save fabric even before a single piece is cut.

This is not just a technical upgrade. This is a cost-saving revolution.

In this blog, you will learn how fabric wastage happens, why traditional methods struggle to prevent it, and how AI can reduce wastage by 8 to 20 percent before cutting begins. You will also discover how small businesses, manufacturers, and designers can use AI tools to save money, improve quality, and design more efficiently.

Whether you work in fashion, textiles, manufacturing, or even if you're just curious about how clothes are made, this article will show you how smart technology is reshaping fabric usage in India and across the world.

Understanding Fabric Wastage: The Hidden Problem in Every Cutting Room

Fabric wastage does not always happen in big, visible ways. Sometimes it happens quietly, in small pieces, wrong alignments, crooked patterns, or miscalculated layouts. Over time, these small losses turn into large financial damage.

Fabric wastage usually comes from four major areas:

1. Wrong Cutting Layouts

Cutting layouts (also called markers) decide how patterns are placed on fabric.

If layouts are not optimized, fabric gets wasted.

A few centimeters lost per garment becomes hundreds of meters per order.

2. Print and Pattern Misalignment

Printed fabrics, stripes, and checks need precise matching:

pockets, fronts, collars, sleeves, plackets, and panels must align.

Misalignment leads to re-cutting, which increases wastage.

3. Human Error and Guesswork

Many cutting masters still rely on manual judgment.

Without exact measurement or digital planning, fabric consumption becomes unpredictable.

4. Unplanned Manufacturing

Different sizes, different styles, and urgent orders disrupt fabric planning.

This causes leftover rolls, unusable pieces, and trimming waste.

Industry Statistic

According to the Textile Value Chain Report, 15 to 25 percent of fabric is wasted during cutting and sampling in traditional garment production.

That means if a factory buys 1,000 meters of fabric, nearly 250 meters can be lost if not managed properly.

Why Cutting Is the Most Sensitive Stage in the Entire Fashion Production

Design can be corrected.

Stitching can be fixed.

Packaging can be adjusted.

But once fabric is cut, there is no going back.

Cutting defines:

• cost

• quality

• fitting

• wastage

• success of the garment

This is why cutting rooms are considered the most important department in any garment unit. The smallest error in marker placement or alignment can cause large-scale wastage, which directly affects the company’s profit margin.

But here is where artificial intelligence comes in as a powerful saver.

How AI Helps Stop Fabric Wastage Before Cutting Even Begins

AI is not a machine operator or a designer.

AI is a decision-making partner.

It analyzes fabric, pattern, style, layout, and consumption mathematics to give you the best possible use of material.

Here’s how AI helps at every stage.

1. AI Creates the Most Efficient Cutting Layouts

Traditional layout making is a manual process.

AI layout creation is scientific, mathematical, and ultra-efficient.

AI calculates:

• pattern size

• fabric width

• garment size distribution

• rotation angles

• placement combination

• leftover possibilities

• direction of the grain

By analyzing thousands of layout patterns in seconds, AI finds the layout that gives maximum usage and minimum wastage.

Result:

Factories save 8 to 20 percent fabric by using AI marker optimization tools.

Many brands in China, Bangladesh, and India have adopted AI cutting systems and reduced their material cost almost instantly.

2. AI Fixes Print and Pattern Alignment Before Cutting

Printed fabrics are expensive and sensitive.

If you cut them wrong, everything becomes useless.

AI checks:

• floral pattern matching

• stripe alignment

• check alignment

• border placement

• panel continuity

• symmetric and asymmetric prints

• positioning for pockets and collars

AI also generates digital previews of how the garment will look after stitching. So, cutting mistakes can be avoided before scissors touch the cloth.

Quote:

“Print mismatch is one of the biggest reasons for fabric wastage. AI minimizes this by predicting alignment issues before production.”

– Apparel Automation Research Institute

3. AI Predicts Consumption Accurately

Manual consumption calculation often fails because:

• pattern shapes vary

• fabric shrinks differently

• size combinations change

• roll width varies

• layout changes per order

AI uses data-based prediction to give exact fabric consumption numbers.

This helps:

• planning

• costing

• ordering fabric

• reducing leftover rolls

• controlling budgets

Accurate consumption means accurate profits.

4. AI Prevents Mistakes Caused by Human Judgement

Humans get tired.

Humans guess.

Humans can miscalculate.

AI does none of these.

AI helps in:

• avoiding wrong measurements

• preventing wrong angles

• avoiding incorrect layout sequences

• preventing double cutting

• preventing misalignment errors

AI keeps the cutting room consistent and quality-controlled.

5. AI Helps Small Designers and Tailors Save Fabric Too

AI is not only for factories.

Small boutiques and designers can also use AI to save fabric.

Examples:

• kurti makers

• blouse designers

• lehenga designers

• tailors

• children’s wear sellers

• small-scale exporters

Even local units can save money using digital layout apps and simple AI-based calculation tools.

Tip:

Take photos of your fabric, upload them to an AI layout optimizer, and check how much fabric each garment consumes before cutting.

6. AI Shows Digital Samples Instead of Physical Ones

Sampling consumes a lot of fabric and involves:

• trial cutting

• trial stitching

• fitting correction

• re-cutting

• editing

• color testing

By using AI digital sampling, designers can view the garment on screen first.

This alone saves 5 to 12 percent fabric in design sampling.

AI-generated samples look extremely realistic.

Clients also approve designs faster because they can see the final look without stitching.

7. AI Helps Reduce Rejection Waste

Rejection happens due to:

• measurement errors

• wrong cutting

• fabric faults

• design mismatch

• uneven fitting

AI can detect errors earlier by scanning the pattern and predicting the final result.

This eliminates unnecessary re-stitching and re-cutting.

Rejection reduction = more profit for the business.

8. AI Helps Solve the Most Common Fabric Wastage Problems

Here is how AI solves real industry challenges:

Problem: Wrong marker placement

AI Solution: Generates optimized markers with 95 percent accuracy

Problem: Print does not match

AI Solution: Pattern alignment preview before cutting

Problem: Tailors cutting based on guesswork

AI Solution: Automated layout recommendations

Problem: Roll leftovers wasted

AI Solution: Predicts roll consumption before cutting begins

Problem: High sampling waste

AI Solution: Digital samples instead of physical trials

Problem: Businesses losing profit

AI Solution: Reduces waste and increases output

Real Factory Example: How AI Saved Fabric in a Surat Unit

A small manufacturer in Surat was producing 3,000 kurtis per month.

They used manual marker making and traditional cutting.

After switching to AI optimization:

• fabric wastage reduced from 16 percent to 8 percent

• monthly savings increased by 22,000 INR

• fewer roll leftovers

• faster approvals

• more consistent quality

This example shows that even small setups can gain huge benefits with AI.

Why AI Is the Future of Fabric Cutting

AI has become a necessity because:

• fabric prices are rising

• labor is expensive

• speed is important

• accuracy is mandatory

• waste must be reduced

• brands want sustainable production

With global pressure toward sustainability, reducing fabric waste is essential for every textile business.

McKinsey Report Insight:

AI-enabled cutting solutions could reduce material waste by up to 30 percent in mass manufacturing.

Practical Tips for Using AI to Reduce Fabric Waste

Tip 1: Always Digitize Fabric Rolls Before Cutting

Use a camera or scanner to upload your fabric digitally.

Tip 2: Check the Layout with AI Tools

Never cut without checking the optimized layout.

Tip 3: Use AI for Pattern Matching on Printed Fabric

This saves your most expensive materials.

Tip 4: Use AI to Predict Fabric Consumption

Plan orders smartly and avoid overbuying.

Tip 5: Combine Human Skill with AI

Human experience + AI accuracy = perfect results.

Tip 6: Train Your Cutting Team

Even basic knowledge of AI tools increases efficiency.

Final Thoughts

Fabric wastage is one of the biggest hidden losses in the textile and fashion industry. For many years, businesses accepted this wastage as normal. But now, technology has changed everything. Artificial intelligence gives designers, cutters, manufacturers, and small business owners the power to reduce waste before cutting even starts.

From optimizing cutting layouts to predicting consumption, from matching prints to generating digital samples, AI creates a complete cost-saving ecosystem. It gives you more profit, better quality, and a more sustainable future.

If you want your business to grow faster and waste less, adopting AI is not a luxury anymore. It is a smart investment that pays you back every single day.